The Rise of Quantum Computing in Automotive Industry

Quantum computing has the potential to revolutionize the automotive industry through its advanced capabilities in optimizing vehicle design. With quantum computing’s ability to process massive amounts of data and complex algorithms simultaneously, automakers can enhance their simulation models to improve vehicle aerodynamics, safety features, and overall performance. This technology enables more accurate and rapid analysis of various design options, leading to the development of more efficient and innovative vehicles that meet consumer demands.

Moreover, the implementation of quantum computing in the automotive sector can enhance autonomous driving systems. By leveraging the computational power of quantum processors, car manufacturers can improve real-time decision-making processes, sensor fusion, and predictive maintenance. This has the potential to significantly enhance the safety and reliability of self-driving cars, making them more capable of navigating complex environments and reducing the likelihood of accidents.

Current Challenges Faced by the Automotive Industry that Quantum Computing Can Address

The automotive industry is facing a multitude of challenges in today’s fast-paced world. One of the key issues is the need for advanced optimization algorithms to enhance manufacturing processes and supply chain management. Traditional computers struggle with the complexity and volume of data involved in these operations, often leading to inefficiencies and increased costs.

Furthermore, the automotive sector is constantly striving to improve vehicle safety through the development of advanced driver assistance systems (ADAS) and autonomous driving technologies. However, the intricate calculations and decision-making processes required for these systems demand immense computing power that current technology may not be able to handle efficiently. Quantum computing offers the potential to revolutionize this aspect by providing faster and more accurate simulations, leading to safer and more reliable vehicles on the road.

Quantum Computing vs Traditional Computing in Automotive Industry

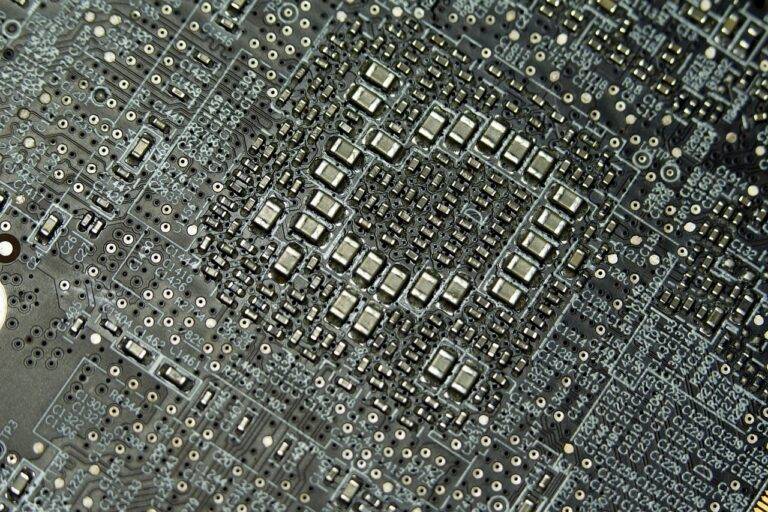

Quantum computing has sparked significant interest in the automotive industry due to its potential to revolutionize various processes. Traditional computing relies on bits to store and process information, while quantum computing harnesses quantum bits, or qubits, which can exist in multiple states simultaneously. This allows quantum computers to handle complex calculations much faster than traditional computers, making them well-suited for tasks like optimizing vehicle design, traffic flow, and logistics.

In contrast, traditional computing has limitations in tackling the massive amounts of data generated by autonomous vehicles, smart traffic systems, and manufacturing processes. Quantum computing’s ability to process vast datasets and perform parallel computations offers a promising solution to these challenges. By leveraging quantum algorithms, the automotive industry can enhance vehicle safety, improve energy efficiency, and accelerate innovation in areas such as self-driving technology and predictive maintenance.

What are some potential applications of quantum computing in the automotive industry?

Quantum computing can be used for complex simulations and optimizations in vehicle design, improving fuel efficiency, enhancing safety features, and optimizing supply chain management.

What are some current challenges faced by the automotive industry that quantum computing can address?

Some challenges include optimizing traffic flow, reducing emissions, improving battery technology for electric vehicles, and enhancing cybersecurity measures in connected vehicles.

How does quantum computing differ from traditional computing in the automotive industry?

Quantum computing utilizes quantum bits or qubits to perform calculations at a much faster rate than traditional bits. This allows for solving complex problems more efficiently and effectively, leading to advancements in vehicle design, manufacturing, and operations.